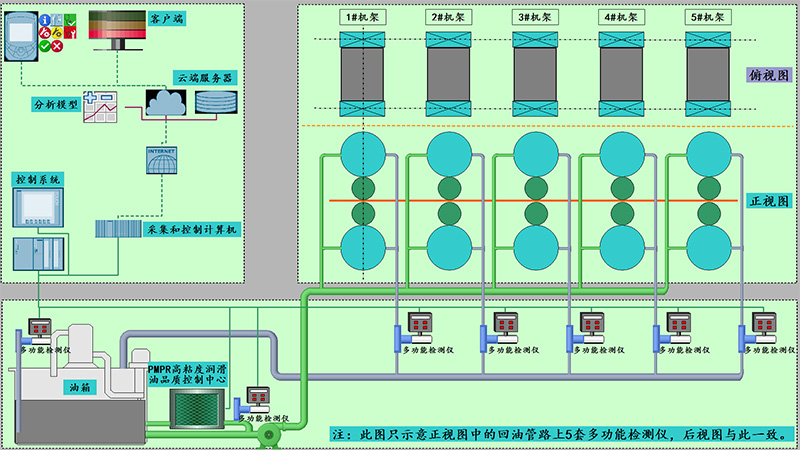

The intelligent monitoring and operation and maintenance system of rolling mill lubrication is reformed from the existing lubrication system. The SYSTEM IS equipped WITH MULTI-function oil detector at roller bearing, lubrication system pump station, etc., which is used to detect the running state data of friction pairs (bearings) and lubricating oil in the rolling mill lubrication system. The data are collected by the field controller and transmitted to the analysis model computer for predictive analysis.

The prediction results after the model computer analysis will automatically feed back to the PMPR lubricant quality control center to execute the oil repair instruction. At the same time, the system will include the normal running state, warning, fault and other data in the model computer and the client for real-time visualization interface display.